KiCad notes: The one-timer PCB maker’s hints for the next time

Intro

These are my notes to self for the next time I’ll have a PCB design to make. This is definitely not my expertise.

My original intention was to start this post with some kind of apologize, saying I only needed to make a simple board, so KiCad was good enough for this purpose. However it seems like KiCad is about to become the preferred tool many PCB designers quite soon, if it’s not there already. It’s surely handy and relatively easy to learn (at least for me, an experienced Electrical Engineer with no previous hands-on in board design). Does it match up with the expensive tools out there for a heavy and complicated design? I don’t know.

Everything in KiCad is text based in a simple manner. Important for version control, and using it to monitor my changes. Also very handy for fiddling with the files to get the things right on spot. In particular useful when creating footprints.

All said here relates to KiCad 5.1.4 under Linux Mint 19.

Getting started

- The KiCad version that went along with Mint 19 was heavily outdated. Compare what packages are available directly from KiCad.

- When upgrading from 4.x to 5.x, be sure to uninstall the previous version and purge it (apt purge) before installing the new one. Also, delete .config/kicad/ as it contains the paths to libraries for symbols and footprints.

- The ‘Footprint library path “…” does not exist’ error may be a result of not cleaning up an old installation as mentioned in the previous item.

- The official documentation, in particular the Getting Started with KiCad guide, is definitely the right place to start and refresh memory.

EESchema

- Before starting to work: Verify that the page size is correct and that the grid is 50 mils or so, no lower: View > Grid Settings… to ensure this.

- Basic components: In the “Device” library.

- Aiming the cursor on something accurately and right-clicking is usually the start for modifying virtually anything.

- Better still: Note the hotkey and use it while hovering over the relevant place.

- “Drag” keeps connections. “Move” doesn’t. Use “Drag”.

- If wires don’t snap to the ports, and components are placed regardless to the grid, it’s most likely that the grid is too dense.

- Useful hotkeys: Hover-Delete (well, delete), Hover-G (drag, think Blender) and Hover-C (duplicate).

- “Value”: Each component has a value assigned to it. The value appears on the assembly layer (F.Fab or B.Fab) of the PCB. In other words, the person doing the assembly of the board will see this value in the component’s position, and select what to put there accordingly. For resistors and capacitors, it’s obviously the value of the component. For other components, a useful hint on the nature of the device should be there.

- “Reference”: The symbol’s unique identifier in the schematics and netlist. U1, J15, C225 etc. By default, they’re C?, R? etc. until Annotate Schematic… is done.

- Net names: Designated with “Place Net Label” or by pressing “l”. Makes things easier during layout, and differential pairs must be with “+” and “-” suffixes (or _p/_n), or PCBNew won’t play ball later on.

- Footprints are assigned on each component’s Properties (and are not associated with symbols, unlike other tools), or more conveniently, with Tools > Assign Footprints. The association affects the schematic (.sch) file, appearing as a string property consisting of the library name and the footprint’s name, separated by a colon. Don’t associate to library footprints, but copies of them, defined explicitly on a local library. Or upgrading KiCad may change the design. See below on footprints.

- Plain holes are “virtual components”. Add a MountingHole symbol for each, and assign a matching footprint (hole only).

Symbol Editor

- Read the Symbol Guidelines in KiCad Library Convention document (KLC), after the daunting naming convention part (start at S3, maybe). It’s how to get it right.

- Check the grid. 50-100 mils, or the wires won’t snap to ports when the symbol is used (official guideline is 100 mils).

- Symbol Editor: When drawing a rectangle, click at the corner points, don’t hold the mouse button.

- It doesn’t hurt setting the “Description” property for each symbol — it appears on the library’s list as well as the output netlist.

- If a pin has multiple pads assigned to it, KiCad expects them to have track wires on the PCB connecting between them all.

Understanding footprints

Footprints are a set of graphical shapes in different layers that serve several purposes, all of which much be addressed when setting up a custom footprint:

- Putting the pads in place: Front copper layer (F. Cu, and also B. Cu with thru pads) and solder mask (F. Mask). Actually, the solder mask layer is the hole in the solder mask. Even though the shape of these is the same, the solder mask is widened slightly when Gerber files are created.

- Solder paste: When used, where the stencil holes should allow solder paste to be applied (F. Paste). As with solder mask, the shape is usually the same as the pads, but the datasheet may require a different pattern.

- Holes (drilling): These are a side effect of thru-hole pads, and appear in the footprint layers as is there was copper there.

- Silk Screen: Descriptive information on the board, in particular the component reference (F. SilkS)

- Assembly: Mark the place where the device actually is (F. Fab). The placement’s origin should also be the footprint’s (x,y) origin for automatic placement. The reference designator (“%R”) is written inside the component’s boundaries, and its “value” (what it is) typically underneath.

- Clearance: Ensure that nothing else is placed in the space that the device requires. This no-place space is called “courtyard” (F. CrtYd). The idea is simple: If, during layout (with PCBnew), the courtyards of two components overlap, it’s a DRC error at the very least, and possible also a refusal to generate Gerber files. So the courtyard should be the area that the component must occupy exclusively.

The layer assignment assumes that the component is placed on the front. When placing on the back side, the Layout Editor flips the layer assignment as necessary.

Holes is a bit tricky, because they are an implicit result of pads with holes. In particular, NPTH is Non-Plated Thru Holes, and appear in the footprints as pads of this type.

Footprints

There’s another post of mine, which discusses pads and footprint manipulation.

- Rule number one: Copy or imitate an existing library footprint rather than reinventing the wheel. Preferably imitate one that is likely to be heavily used.

- Read the Footprint Guidelines in KiCad Library Convention document (KLC). Skip the naming convention, and start at F4 (or so). This might be the best source on the planet for setting up a footprint. Odds are that these rules are tuned based upon real-life experience of a lot of people.

- Never ever use a footprint directly from the libraries to a component in the design. That makes the outcome dependent on the KiCad version running.

- Rather, create a project-dedicated footprint library (a directory with a .pretty suffix) in the Footprint editor, and put it in the Project’s library table. Then open the desired footprint in Footprint editor, and save it into the project’s library.

- Note that the 3D model still points at a KiCad library even after this, but that’s less important.

- Monitor the changes with git. It’s quite straightforward and allows a safe double-check.

- Don’t hesitate editing the footprint file manually, in particular for nailing exact positions. Exit the Footprint Editor and re-enter it, and then load the footprint. Using “Revert” for updating changes won’t work.

- To verify that a footprint is OK:

- At the very least view each layer separately, and make sure it contains what it should. Drill holes are covered by absence of material in the copper layers.

- Verify that SMT pads cover F.Cu, F.Mask and F.Paste (check each separately!). For thru pins, also on the back.

- Read through the text file (with _mod suffix) and look for unexpected stuff (one pad having different dimensions for no reason etc.)

- Pads may not have a pad number. This is useful for e.g. stencil pattern not matching the shape of the pad.

- If multiple pads have the same pin number assigned to them, track wires must be connected between them during the layout.

- Pads and other elements may very well not be on the footprint nor layout grid. I find myself calculating their X/Y position rather than placing them, so any position goes.

- For adding anything other than a pad, the drawing or text falls on the layer marked with a small arrow in the list of layers.

- Text substitutions: %R is replaced with the reference, %V with the value.

- Even though the name of the footprint is shown as the “value” in the Footprint Editor, it will be the component’s “value” field in Pcbnew. So it’s useful information during assembly of the board.

- Right-click on a pad, select “Array” to produce several identical pads with equal spacing. In extreme cases, write a simple script to manipulate the footprint file directly (exotic positions or pad naming).

- Use the measurement tool for assurance. It snaps to the grid.

- Any line thickness is implemented as a filled circle drawing along the line. This makes rounded corners.

- Pads can have arbitrary shapes. See this post.

PCBnew (layout)

- When starting a new project, remove the *.kicad_pcb file as well as .config/kicad directory, and start from scratch. KiCad’s defaults are usually good, so if a detail is overlooked, better have the default than some previous setting.

- File > Board Setup… and set the board’s thickness, trace parameters etc. It’s also a good idea to define the net classes (in particular high frequency nets).

- PCBnew depends on the current netlist as well as the footprint libraries. They are updated only on explicit request, so each time the schematics or footprints in use are updated, the changes must be synchronized by user request. As for the schematics, there an “Update PCB from Schematics” button. Or export the netlist from EESchema in default format and load it into PCBnew. It’s fine to do this iteratively (and even finer when covered by version control to cover up for mishaps).

- Grid: Pads may be off the grid, and there’s no problem selecting them as a start and end point for a route. The track itself will generally go on the grid, except for leaving it in order to reach a pad in a sane manner (usually with a 45-degree detour, not on a grid point). The grid pitch should hence be the approximately most used track width + the track clearance if a dense design is desired. Possibly make it in line with crucial footprints’ pitch, to keep straight traces, aligned with the grid.

- Ratsnest: Straight lines showing connections between pads. View all at once with View > Show Ratsnest (default on) or turn off, and view individual lines with “Display local ratsnets” icon on the toolbar to the right.

- The origin’s position has no significance, expect that it places the grid. However the absolute position values appear in the Gerber files, but this can be fixed by adding an auxiliary axis (more on this below).

- There are no 90 degree turns on tracks (except for power lines), only 45 degrees (and possibly smaller angles when aligning to the grid). Feels a bit awkward in the beginning but sharp turns are evil.

- There is no dragging of components (footprints), only moving them, which results in disconnection of all tracks going to it.

- While drawing tracks, press “v” for a via, press “/” to change the posture (the position of the 45 degree detour, if present).

- Always start and end a track by clicking at the center of a pad (the “anchor”), in particular if it’s off-grid.

- Ground / power planes: Create a fill zone, which is a polygon which is designated to a net. After setting up the zone, select it, right-click and pick Zones > Fill. This may not work unless there is already a track with the desired net going through the area. The track may remain, as it’s harmless. It’s probably the via, which connects the area to the net that does the trick. Once set up, a via is enough to connect to the plane.

- Repeat the zone fill after each change that may affect it.

- If the zone fill gets too close to a specific footprint’s pads, open the “Local Clearance and Settings” tab on the footprint’s Properties, and set a larger (actually, non-zero) clearance.

- In the end, tracks are a sequence of segments with a start and end position, width, layer and net designation in the *.kicad_pcb file (with “segment” keyword), vias are elements with the “via” keyword etc. Everything is absolutely positioned. Therefore moving a component (actually, its footprint) disconnects everything. All in all, PCBnew is just a smart drawing program for geometric shapes.

- Differential pairs: Route > Differential Pair. Then Route > Tune Differential Pair Skew / Phase, in order to check the skew and possibly tune it (or possibly move a component if that helps).

- Setting the parameters for track length and skew tuning: After selecting the track to tune, instead of moving the mouse to get those humps, right click and select Length Tuning Settings (or CTRL-L). The amplitude and length of these humps can be set, as well as the target length (instead of the default 100 mm).

- There’s a measurement tool (“Add dimension”) which is handy to verify certain distances, in particular the dimension of the board. The tool shown an indication when it’s on a line end, so one can be sure the accurate measurement is made. Best done on a separate drawing layer.

- Optionally, add an auxiliary axis origin to the layout, placing the (0,0) point of Gerber and drill files. This changes the aux_axis_origin parameter of the PCB design from (0 0) to whatever it was set to, and the coordinates in the Gerber files will have an offset relative to the layout files. Useful if the entire layout was drawn with some meaningless origin position. Then check “Use auxiliary axis as origin” when generating Gerbers and drill files.

3D viewer

I didn’t understand the point of a 3D view at first, but it’s surprisingly helpful, in particular during PCB layout — even though it’s also handy with the Footprint Editor. There’s something reassuring seeing the silk screen as white text on a green solder mask, and the drill holes as see-throughs. Click the mouse’s middle button to move the scenery.

Launch with View > 3D viewer (or Alt-3).

Generate Gerber files

You have reviewed the DRCs in EESchema and PCBnew, right…?

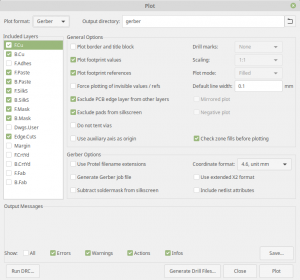

So to the final check before taping out. Export the files in PCBnew with File > Plot… and as follows (for a two-layer design):

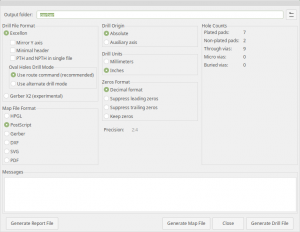

and then generate a drill file (click “Generate Drill File”, of course).

All the settings above are KiCad’s defaults, by the way. Changes in these settings are stored in the *.kicad_pcb file for the next time these windows are opened (and not KiCad-globally).

Note that two drill files are (usually) generated: One for plated holes (vias and pads) and one for non-plated holes (typically mechanical holes for mounting).

A component positioning file can be generated with Fabrication Outputs > Footprint Position (.pos) file, however this file uses the internal footprints and their names. In particular, if the footprint’s origin isn’t where the automatic placement machine thinks it should be, the device may end up in the wrong place.

Viewing Gerber files

KiCad’s Gerber is fine, but it’s recommended to install gerbv as well (plain “apt install gerbv” on Mint 19). It’s part of gEDA, and it allows changing the order of the layers, but even more important, to export the current view to pdf. KiCad’s viewer prints one layer per page, and it’s hardly helpful. Use the export feature, don’t print — the latter generates a microscopic printout.

The main motivation for printing layers is to print the fabrication layer (preferably without values, KiCad has that option) on top of the edge cut and possibly a copper layer. For manual assembly, this gives a good indication of what goes where. To run it, just go

$ gerbv &

For KiCad’s viewer, load both the Gerber files and the drill files into Gerbview, and take a close look. The layers are displayed in the order they were loaded, so load the drill files first. As they are usually loaded with multiple selection of files, that’s probably alphabetical order, putting the bottom layer above the front.

Right-click on the layer list and select “Sort Layers if X2 mode” (should be “in X2 mode”, I guess) for layers ordered in physical order.

The active layer is always visible (drawn last).

Most important: Verify that the drill holes, plated and not, are in the correct places.

The DCodes are the aperture with which each line is drawn. An aperture is like a paintbrush, which is defined in each Gerber file for its own drawings. It’s usually a filled circle or rectangle with specific dimensions. The benefit of having these on the screen is to identify tracks with the same width and pads with the same dimensions, if they have the same DCode and are on the same layer. The same DCode on different layers (and hence Gerber files) has no meaning. For example, D10 and D11 are typically the DCodes of the first apertures defined in Gerber file, and are practically on every layer.

Create assembly sheet

If the design is going to be hand-assembled, better have a simple drawing that tells what goes where. To do this, plot the Gerber files as before, but uncheck “Plot footprint values” (but keep “Plot footprint references” checked, of course). Check F.Fab layer for plotting.

Recall that PCBnew remembers this in the *.kicad_pcb file, so be sure to revert it (with git) afterwards.

Next, open the files with gerbv (not KiCad’s Gerber viewer). Display the F_Fab layer, which should have the component references printed small inside boxes, along with the edge cuts and a copper layer. Change the colors for convenience.

Then File > Export > SVG… and generate a file. Import that file into a Libreoffice Writer document, and export that document as a pdf. Why not directly as pdf? Because the output pdf is broken, and even when I managed to open it, turning it into a pdf with a decent size turned out impossible.

A similar SVG export can be done from PCBNew: Pick File > Export > SVG… and select “Board area only” under “SVG Page Size”. For Pagination, pick “All layers in a single file”. However I haven’t figured out how to get rid of the values, and they clutter everything.

Manufacture

- Holes: Manufacturers typically make the hole slightly larger than required, as commented on this thread. The difference is typically no more than 0.1mm, so it’s not a big deal.

- PCB material: FR-4 is de-facto industry standard for rigid boards. 1 oz copper thickness is by far the most common. Pick thicker only for high currents. Board thickness: 0.6/0.8/1.0/1.2/1.6/2.0 mm. Tolerance is typically ±0.1 mm.

- Drill size: 0.2 – 6.3mm (but don’t go lower than 0.4 mm = 16 mils for basic PCB)

- Trace width: 6 mil seems to be a common minimal trace width, but Protel used to set 10 mil as the default (the latter seems to carry up to 1A, but check with a calculator). Unless there are current to carry, stick to these figures in general.

- Minimal trace space: 3 mil seems to be possible, but 10 mils should be chosen unless there’s a reason to push it. Minimal trace to board edge clearance should be 0.3 mm, but standard edge connector footprints tend to take 0.5mm for their pads. So better go for the latter.

- All in all, it seems like 10 mils for minimal trace width and space, and 0.4mm mils for vias are the sane choice. If the board gets tight, go smaller.

- If the board has an edge connector (“Gold Finger”), it’s ENIG (Electroless Nickel Immersion Gold) surface finish (sometimes referred to as just Immersion Gold). This is required only at the edge connector itself, because the gold’s role is to ensure good contact. According to the IPC-4552 standard, the default thickness of the gold layer is 0.05μm (sometimes referred to as 2U”). Sometimes ENIG is offered as the finish only for the edge connector, but this is relevant only for a large board. For a small board like mine, ENIG applies to the entire board.

- The assembly is the expensive part. Manufacturing should be at around $5-10 for 5 copies for a small board.

- HASL is not RoHS compliant, because of the use of lead. Lead-free HASL should be used instead (or any of the other, more expensive, options).

- Gerber files in RS-274x format for board outline, copper layers, silk screen(s), solder masks and solder paste. NC drill sometimes required in Gerber format instread of Excellon.

- NC Drill file, in Excellon format

- For assembly, this page summarizes it well. An assembly sheet as described above is a good idea.

Finding a manufacturer

My board involved small SMT components, so no chance to do the assembly myself. Actually, 10 simple components, on a plain FR4 53 x 22 mm board with two 1 oz layers and an edge connector (hence ENIG finish). The price for a turn-key project is at least $100. Don’t expect less.

And the minimal order quantity is 5. Everywhere.

The place to make a comparison is PCB shopper. I also suggest look at Manufacturing Reports for some painfully detailed reviews on PCB quality. If you need assembly (PCBA service, A for assembly), select service by assembly costs, as it’s going to be the dominant part.

So these are the estimated prices I got for a small board.

- Smart Prototyping, assembly at $80.

- Elecrow, assembly at about $106.

- PCBWay, assembly at $30 as a Turnkey project, $88 as kitted or partly kitted. Something tells me they’re going to charge a lot for the devices. They do send stuff with regular E-Packet = 16 days.

- ShenZhen2U, assembly at $50 (pretty much fixed price), allowing plain mail shipping. Headquarters in Hong Kong, but apparently the factory is in Shenzhen (China).

I have no affiliation with any of these companies, and this reflects the situation as of September 2019.

These costs didn’t change much when I changed the parameters of the assembly task. It’s sensible to assume it’s mostly the tooling cost (the cost for programming and setting up the automatic manufacturing equipment).

So I sent the files to PCBWay and ShenZhen2U. My personal impressions:

- PCBWay: Nice web interface, quick and professional response (an hour or so, during Chinese daytime). The price difference between the turnkey and the kitted was indeed a hint to their tendency to make up for the low assembly cost by adding fees everywhere: The components were 50-100% more expensive than Mouser (in low quantity prices). When I asked about it, I got some BS answer that it’s more expensive for them, taxes etc. PCB manufacturing at $39, which is pretty high. And they add $8 Paypal fee and $20 for shipping and handling with E-packet. And then there’s an “assembly promotion discount” of $30, ending up at $108 next to the “Confirm & Pay” button.

- ShenZhen2U: Slightly slower response (1 day each time), the website is slightly less useful. The flow was that I ordered the assembly first, then a few emails back and forth (I filled in their BOM form, where I also defined the PCB, and then got an accurate quote) and then the order at the website was updated manually to reflect their quote. They stood behind the $50 assembly cost. Their BOM costs are only slightly higher than Mouser, and they charge $10 for E-packet shipping. PCB manufacturing at $26, which is pretty low. All in all $110, when paid though Paypal (including a Paypal fee of $4.86, which they were clear about and is reasonable).

So there we have it: Almost exactly the same bottom line. One company reached it after fiddling with the prices, and the second just listed them upfront. This is why I went for ShenZhen2U, even though its review on Manufacturing Reviews complained a lot about dirt and bad silkscreen. The parallel review for PCBWay complained about traces being too thin, which is much more serious IMHO.

My experience with ShenZhen2U is overall good: Even though there was very little communication with them, they manufactured and shipped the boards fairly quickly (I selected very slow shipping and was explicit about the project not being urgent). The five boards arrived, one of which had a defective Micro-B USB 3.0 connector, which short-circuited two pins under a certain mechanical load. This issue showed only with a certain (wiggling) USB plug, so I can’t rule out that they actually tested this connector but didn’t spot the issue because they used a proper USB plug, and not what I have.

As a surprise bonus, they sent a bunch of unassembled boards along. Doesn’t hurt.

Other than the said connector, all boards were OK. As they were manually assembled, there were slight imperfections that are seen in a very detailed view, but the work was definitely good enough for functional purposes. So all in all, the work was good, the price very good, and there was a sense that they know what they’re doing — this is me appreciate that there were zero misunderstandings on those unspoken details. I’m probably going to stay with these guys, and not just because of the price.

I then followed up the same project, with a production of 110 pieces with the same company (ShenZhen2U). In June 2020, I got it done at $690, including everything and shipping with DHL — which is a reasonable price drop for the amount. They got it done quicker than promised, and the result was flawless. They did the panelizing in a sensible way (following my request on which part of the circuit must be smooth) and all cards except one passed a rather rigorous electronic QA test. The one that failed had the same problem with the connector, which might be my fault this time (I might have broken it while pushing the card into its place). Bottom line: They’re good at automatic assembly too.

Finding a manufacturer reloaded (2023)

Fast forward three years, and I needed to fill up the stock with another round of boards. I would have loved to go back to Shenzhen2u again, but they were not responsive, and probably out of business, even though their website was fully functional (but a running website means nothing, as we all know).

So the initial question is: Should I make a test round of 5 boards, and then go for the 110 boards, or jump to the second phase immediately? Back in 2019, the first 5 boards served the purpose of validating my own design, but this time there’s no need for that. So is a test run of 5 boards really worth its cost? I was in no hurry.

For a project with few components like mine, one can expect that the assembly of 5 boards will be done completely by hand, but for 110 boards a machine will be used. So these 5 boards don’t mean much in that respect.

Quality of PCB? It will probably be the same, if both manufacturing rounds are made at the same place. But I will not be surprised if there are several manufacturing facilities behind a PCB company, so each time I’d issue an order it may be handled by a different facility. So making a test with 5 units doesn’t necessarily mean anything about what will happen when I order 110 of them.

And then we have components. There are a lot of replacement components out there, and some of the companies offered these replacements upfront with a lower BOM cost. And they are indeed much cheaper. But what if they use these cheap replacements without telling me? If they do that with a USB plug, I can tell that by the marking on the component, but what about SMT capacitors and resistors? They can put whatever junk they have. How would I tell?

Fake components is a problem even with the most respectable dealers. I’ve actually had a client of mine receive an FPGA that was completely different and incompatible with the one ordered. Yet the marking on the chip was as the one requested. So it was a deliberate fake job, probably by the component dealer’s vendor. And that happened even before COVID-19 and the shortage of components that came with it.

So a 5 board test round probably gives me an idea of whether they put components that aren’t catastrophic and something about the PCB quality. Plus if there are some China-style unexpected surprises in store. Never underestimate the Chinese capability of doing something unexpected.

Whether this round is worth its cost depends, well, on this 5-board round’s price.

What I learned from 3D printing: The only thing I know for sure about is the price. Higher price doesn’t necessarily mean better quality. Returning to the same vendor doesn’t necessarily mean the same result. So go for the offer in terms of price, unless there are bad omens during the initial communication. The chance for failing is basically the same no matter who I choose, so the strategy is to reduce the stake.

There are plenty of reviews for several PCB related companies. Except for the obvious problem that reviews may not be authentic, there’s also a great difference between the needs and expectations of the person who writes the review. An unprofessional maker who builds a simple 2-layer board is not like a professional engineer who submits a super tight and super-complicated multi-layer board and expects the same quality as an expensive European-standard alternative. That said, I’ve also seen expensive manufacturers screwing up completely. The difference is that the latter speak better English.

Which brings me back to the same conclusion: There is really no bulletproof way to know who to work with. The only thing you know for sure is the price.

Getting started, 2023 version

Even today, PCB shopper was the best place to start. There are also reviews on this website, but I had to Google for them – there was no direct link from the homepage to these review pages (only along with price estimations for a specific board). Even though they are clearly affiliated with some of the manufacturers, it still offers some automatic quotes to start with. Then I used ChatGPT in order to get a few additional names. The question was “which manufacturers are often mentioned along with X?”.

Another starting point is to submit the manufacturing files to PCB Directory. They forward the requirements to some manufacturers, and the quotes from these arrive through email. I got two quotes this way (from HiTech Circuits and CanmTech). Needless to say, use a temporary email for this purpose (I get tons of PCB related spam only because of this page).

That said, I checked how much spam I received to email addresses that I used with PCB manufacturers. Surprisingly enough, absolutely none. Except for direct follow-up offers from the same companies, nothing. None of them disclosed my email to third parties. Maybe I shouldn’t be surprised: These are serious businesses, after all.

Speaking of which, of course I didn’t think about turning to all those companies that have been spamming me for years about their PCB factory. I actually checked all candidates, and none of them had ever sent me spam randomly (“your coupon will soon expire” mails is something I won’t consider spam for this purpose).

Elecrow and Seeed Studio did however send me a newsletter promoting their products after subscription, but with an efficient option to unsubscribe. PCB Directory also sent me a newsletter later on, and I unsubscribed.

As for Manufacturing Reports, it doesn’t appear to have been updated since 2023, so it’s not relevant anymore.

So: Picking a manufacturer, 2023 version

Don’t ask me how and why, I ended up with 7 quotes. I asked them for a full turnkey project (including component sourcing) for 5 boards and 110 boards. These are the prices per board as I got them, in USD, including the lowest shipping option that each company offered and all kinds of weird extra fees. In short, these are the price per unit as it would actually cost me.

The table is sorted according to the price for 110 pcs. Keep in mind that this is a simple small board with two layers and 10 components. YMMV.

| Company | USD/board 5 pcs |

USD/board 110 pcs |

| Elecrow | 18.41 | 4.34 |

| HiTech Circuits | 52.51 | 5.01 |

| PCBWay | 24.49 | 5.24 |

| AllPCB | 39.53 | 5.42 |

| PCBGOGO | 45.80 | 5.84 |

| CanmTech | 32.04 | 5.86 |

| Smart Prototyping | 65.31 | 6.19 |

Don’t get upset if the price jumps up and down throughout the process, and that the estimate of the online calculated might have been too optimistic. Neither how the price is broken down into PCB, PCBA manufacturing, shipping and handling, possibly a separate cost for the stencil and whatnot. The only thing that counts is the total price in the final quote. The rest is just noise that comes from the company’s marketing guys, and they’re out of the way as soon as the order is made, no matter which company you choose.

It’s also fine that their component prices are higher than I can get from Mouser and similar component dealers. They probably get much better prices, yes, but they also add a fee for the work, risk and the extra amount that one has to buy in order to cover up possible mishaps during assembly. Actually, if the price is better that you can get yourself, ask if they didn’t give you a cheap Chinese replacement part, by any chance.

In short: Look at the bottom line only. Never mind how they got to it.

I wrote earlier that the only thing I know for sure is the price, and Elecrow, won with a margin in both quantities. The communication with them was brief, efficient and to the point (unlike several other companies that was between 10-22 mails, just to get the quoting done).

More about Elecrow below…

There were two companies that deserve a comment:

- JLCPCB is maybe the most controversial manufacturer out there. Some love them, some say that they’re a disaster. They have a lot of reviews, for example in Trust Pilot and in Facebook. The reviews of all sorts appear legit, so no doubt there were unhappy people out there. On the other hand, maybe it’s a result of having a lot of customers? Not clear. Anyhow, seeing those reviews, I stayed away.

- PCBWay: Communication with them was really lame and somewhat worrying. I asked for 110 boards, and they said the can only manufacture 125 PCBs. Is that OK? Yes, of course, throw 15 boards to the trash. But then they asked if it’s OK to panelize the board, and if so, if they should depanel them. Even just mentioning the silly idea of not depaneling the boards is worrying. One can only hope that the silliness is limited to their sales, and that the engineering people know better. Regardless, obtaining a quote from these guys was relatively very slow. And tedious.

My experience with Elecrow

They initially suggested a low-cost replacement for the most expensive part, and they were very upfront about it. When I refused, they gave a very reasonable BOM cost (not too low, but neither high).

Placing an order for a turn-key projects was a bit tricky, because their web interface doesn’t suggest how to do that. But I got instructions for that by email, which boils down to this: The idea is to request an online quote for a PCB Assembly, and that allows uploading Gerber files, BOM and files related to assembly. The quote is then found under My Account > Service Orders, and once it has been made, it’s just a matter clicking “Check out” in order to put it in the cart, and then from there to submit an order. The issue of shipping is a bit messed up, because it’s included in the original quote, and then there are shipping options while checking out. So pick “free shipping” to prevent the price from increasing. All in all, their web interface for obtaining quotes and placing orders is not ideal, but once you get the principle it’s smooth.

I put an order for five pieces with Elecrow (92 USD). The Service Orders section in my web account got successively updated as the manufacturing went on, and they uploaded photos of an assembled PCB and even a small video. At some point, I got an email asking me to review the results and confirm shipment.

And this is where things got a little twist. I saw a small notch on the edge of the PCB, which was clearly going to be problematic. But since I only had the picture from one board, and this was a test round, I confirmed the shipment. In this situation, I preferred to see the situation as is, rather than having them fix the problem.

The shipping was quick and smooth, even though I selected a low-cost option: They rely on a postal company that avoids the Israeli postal company (which is problematic lately), so it was a matter of just 10 days. Which is very quick from China.

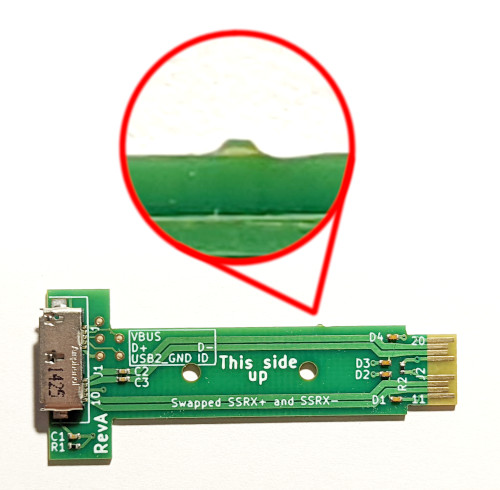

Once the boards arrived, I tested them electronically, and they were all 100% OK. There were no surprises. The correct parts were used, no unsolicited replacements. As for the cutting of the boards, they all had this same notch, as shown in this picture that I’ve taken:

It’s important to reiterate: I saw this problem in the picture that was shown to me before confirming the shipment, and I had the opportunity to complain about it. So even though one can question their QA for passing through something like this, odds are that this would have ended well, had it not been for me insisting to get the boards as is.

I wrote a mail to them, asking for the reason to this notch. The answer I got was that the notch is between the cutting machine’s starting point and ending point, as it makes the trajectory to cut out this small board. They emphasized that this is something that happens only for small-volume orders, and that someone simply forgot to remove the notch manually. As for the rather odd position of this notch, I suppose they manufacture several small boards on the same PCB. So the position was convenient in the context of this larger PCB, I guess.

So the question was whether to continue with them or not. I decided to go on with them for the 110 pieces, mainly because everything was perfect, except for this notch thing. And even if this mishap would have happened on 110 boards, it’s not a big deal to remove the notches with a nail file. Silly, but not a big deal.

The results? Excellent. All 110 boards passed the electronic test with no issues at all. And there was no issue with any notch. I couldn’t ask for more.

What to track with git

For a project named projname, this is the list of files I found sufficient to track:

.gitignore fp-lib-table projname.dcm projname.kicad_pcb projname.lib projname.pretty/*.kicad_mod projname.pro projname.sch sym-lib-table

as for .gitignore itself, this is my somewhat bloated file, which eventually did the job.

*-save.pro *-cache.lib *-rescue.lib *-save.kicad_pcb _autosave-*.* *.kicad_pcb-bak *.000 *.net *.net~ *.bak *.sch-bak *.bck *.gbr *.drl *.pos *.wrl *.csv *.rpt *.step *.stp *.svg *.ps *.pdf *.dxf *.plt *.cad fp-info-cache *~

This ignores files produced by KiCad as well as backups. Plus a lot of garlic against files that were never seen.

Reader Comments

kicad.org is now the official web site that should be linked to. The old domain kicad-pcb has been purchased by someone unaffiliated with the project and could potentially deliver malicious content.

https://forum.kicad.info/t/warning-avoid-all-links-to-kicad-pcb-org-use-kicad-org/31521

Thanks. I’ve updated the links on this page. For the record, it only required changing the domain name. The other parts of the URLs remained intact.

Nice post! I was never exposed to Kicad before but heard about it good things. I’m used to Altium Designer which is working well but I can tell that even the 2021 version still has some issues I need to workaround. I assume that for simple PCBs Kicad can be a great tool.

P.S I think we have talked on the phone maybe 10 years ago, I’m from Haifa as well.